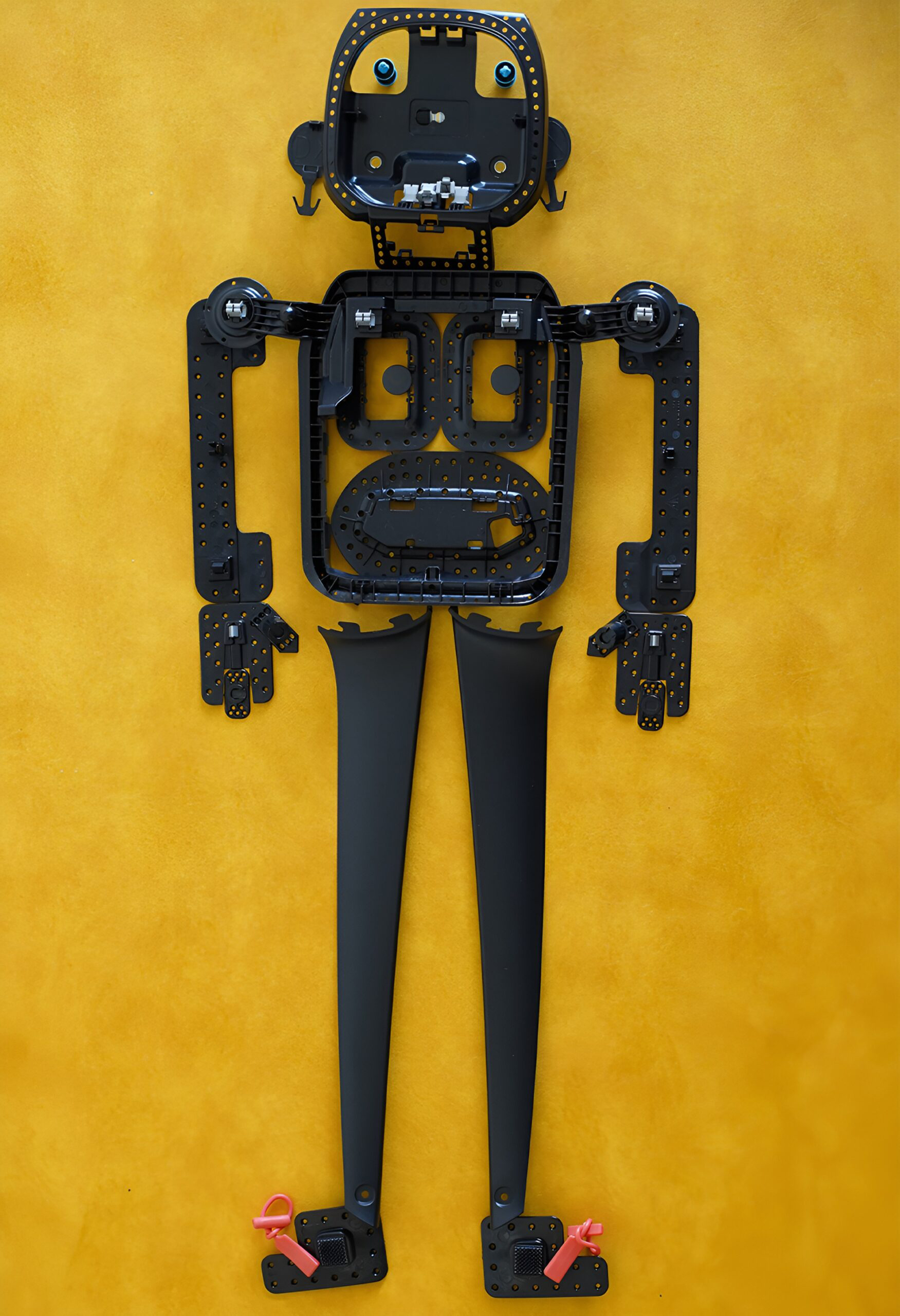

Molding and Molding Plastics

Texline was established in a small hamlet of Civitella del Tronto located under one of Italy's most beautiful attractions, "The Fortress." It started its activitiy in the textile sector with the production of woven cords and ribbons then in 1999 it had its first boost in the automotive sector as a TIER 2 supplier with the production of the co-molded cords for parcel shelves. From then on, the company consolidated and established itself in the sector, for which it now produces about 1300 items for several OEMs such as: Lamborghini, Ferrari, Maserati, BMW, Roll Royce, Porsche, Fiat, Alfa Romeo, Volkswagen, Audi, Opel, Aston Martin, MC LAREN and Seat.

At the same time, Texline manufactures components for other industrial sectors, such as cosmetics, energy and windows and doors. With the experience gained, we try to grow further and perfect ourselves more and more, supporting the customer 360°, from the initial request, through all the subsequent stages, until the after-sales phase.

Offriamo al cliente anche lavorazioni successive allo stampaggio, come l’assemblaggio di accessori sulle plastiche stampate come (ad esempio, clip, viti, bulloni, inserti, dual look, tappini etc. ) acquistandoli o producendoli (tra le nostre realizzazioni: nastrini, gommini, feltrino etc.).

Achievements.

More than 1300 automotive components in serial production.

Learn more

Services

Sectors

Our company has always stood out in the market for the excellence of our services, the quality of the materials we use and the comprehensiveness of our approach. This philosophy allows us to handle all the stages involved, including design, mold manufacturing, plastic parts molding, assembly and logistics for various industries. Our ability to meet the needs of different industrial sectors is based on our mold manufacturing processes, that are extremely flexible and can be adapted to the specific needs of each customer.

- Automotive

- Cosmetics

- Window frames

- Energy

- Other sectors

2460

Progetti Realizzati

Clienti Soddisfatti

Automotive and industrial sector

Our specialization in the field of production of molds for the injection molding of plastic materials is undoubtedly focused on the automotive industry, which represents our main business. We have established a solid relationship with the world of motors: we are responsible for the production of moulds for components used by leading Italian and international car manufacturers. We are also able to provide a complete service to customers, accompanying them at every stage of the process, from design to the production of plastic parts and accessories. In addition to working on aesthetic components, we also develop technical items, such as thermoplastic vowen cords for parcel shelves, airbag caps, safety seat belt buckles, fuel tank cap systems, and door panels.

Certifications

Green

Thanks to the photovoltaic panels installed on the company's own shed, the company is able to use up to 57 kW of regenerated energy during production.

Automation

We optimize the stages of the production process through state-of-the-art machinery and interconnected internal software.

4.0

Texline's goal is to increase productivity and improve working conditions through our constant interest in new technologies.

Smooth Management and Rigorous Controls

ISO 9001 certifications

Download now

IATF 16949:2016 certifications

Download now

ISO 9001 certifications

Download now

IATF 16949:2016 certifications

Download now